Which ENO® packaging machine is best suited to my production output?

We analyze your packaging requirements and production quantities to recommend the right machine.

Whether you need a compact semi-automatic machine for smaller quantities or a high-performance fully automatic machine for 24/7 operation – we deliver the solution that best suits your needs, available space and budget.

What do I need to consider when choosing between a semi-automatic and a fully automatic machine?

The decision depends on your packaging quantity, process structure and personnel capacity.

A semi-automatic machine is ideal for medium quantities with flexible product sizes, while a fully automatic machine offers maximum efficiency, consistent wrapping quality and reduced personnel requirements.

How can the ENO® machine and consumables be optimally matched?

The machine and stretch film must be in perfect harmony to optimize holding force, film consumption and process speed.

We check your existing equipment, analyse the settings and make specific suggestions for fine-tuning and increasing efficiency.

How does the optimization process work, in which ENO® analyzes my current situation, costs and benefits?

We determine your current situation, calculate your packaging costs per unit and identify potential savings.

We attach great importance to transparent, comprehensible figures and combine analysis with practical advice – factual, correct and understandable.

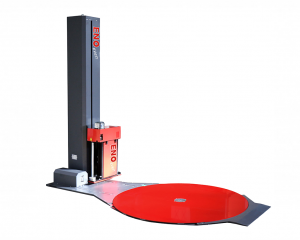

Which mobile or free-standing stretch wrappers does ENO® offer and what are they suitable for?

Our mobile stretch wrappers are particularly flexible and can be easily deployed at different workstations – ideal for companies with changing packaging locations.

Freestanding pallet wrappers offer maximum stability and efficiency for series packaging in continuous operation.

How quickly does an ENO® machine pay for itself through savings in film costs and increased efficiency?

In many cases , ENO® packaging machines pay for themselves after just a few months.

Lower film consumption, reduced personnel costs and shorter packaging times result in sustainable cost benefits and measurable savings.

What safety and ergonomic features do ENO® packaging machines have?

Our machines are designed for safety, user-friendliness and ergonomics.

Automatic film feeders, smooth-running turntables, emergency stop systems and intuitive controls reduce stress and ensure safe operation.

What services does ENO® offer in addition to the machine (e.g. maintenance, advice, spare parts)?

We support you beyond the purchase with comprehensive service, maintenance, spare parts supply and training.

Our experts are always available for technical support, process optimization and operator training.

Can I also get machine solutions for specialized applications (e.g. extremely low height, special format) from ENO®?

Yes, we develop individual machine concepts for special requirements – e.g. for low installation heights, special product shapes or special film properties.

Together with you, we realize tailor-made solutions for every packaging situation.

How is an ENO® packaging machine installed and commissioned - and what training is included?

Installation is carried out by our trained service technicians directly at your premises.

After commissioning, you will receive instruction and training so that your team can operate the machine safely and efficiently – for a smooth start to the packaging process.

With us, you get everything from a single source! We determine your current situation, calculate your costs per packaging unit, factually, correctly and in a way that is easy for you to understand. With our many years of experience, we support you in the search for and selection of packaging solutions.