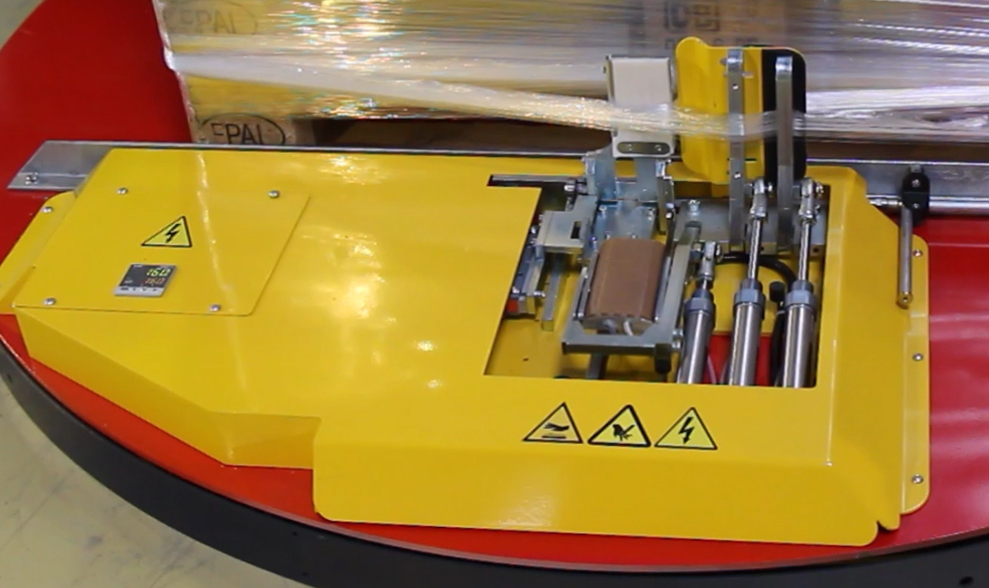

Foil separating and sealing device with clamp

Collision protection on the film carriage

Adjustable turntable speed

Base frame – painted welded steel construction

Electronic control panel with 32 storable main programs and display lock – Freely definable programs

Height sensing by photocell

Film carriage with motorized pre-stretching

Electronic control, pallet counter

ENO® CO PLUS

Another innovation among stretch wrappers! This system does NOT weld against the product.

Info

- Semi-automatic stretch winder for professional use.

The stretch wrapper for high pallet performance and optimum flexibility in terms of goods and transport safety. - The process is largely automated via a pneumatic contrast with electrical film separation and film welding.

This equipment does NOT weld against the product.

Facts

-

- Adjustable number of foot and head windings

- Adjustable carriage speed

- Up to 32 programs can be stored

- Turntable 1.650 mm

- Winding height 2,200 mm

- Pallets weight: max.

2.500 kg - Soft start and stop

Film slide version:

- Film slides with motorized prestretching included Staged prestretching with changing ratios (ex.150/200 and 240%)

- Pre-stretching system 2-motor steplessly adjustable up to 400 % stepless contact pressure

Function

- Function: Position the pallet correctly on the turntable.

- Start the desired or preset winding program via the control panel.

- The pneumatic film holding system holds the stretch film at the beginning and enables automatic stretching of the pallet.

- After completing the windings, the film is wound over a contrast and held in a clamp.

Then the foil separation and the final welding of the foils takes place. - During stretching, the machine detects the package height by means of a photocell, and the program runs automatically.

Service - Everything from a single source

With us you get EVERYTHING FROM A SINGLE SOURCE!

- Take advantage of the flexible service, knowledge and experience of our technicians.

- We keep many spare parts permanently in stock, ready for you to call off quickly.

- Through regular maintenance of your packaging machines, you prevent breakdowns & downtime.

- We offer rental also for balancing seasonal peaks, installment plan, or our own very favorable leasing offers.

- Suitable for your application, optimised for your machine(s). We offer the full range of stretch film from our own production at market prices!

If problems arise, there is always just one contact person who can help quickly and competently.

Consumables

In combination with our film types: “ENOevopower” or “ENOfuture” (depending on the packaged goods and the lifting slides used), extremely stable load securing is achieved at the lowest possible cost. INFO