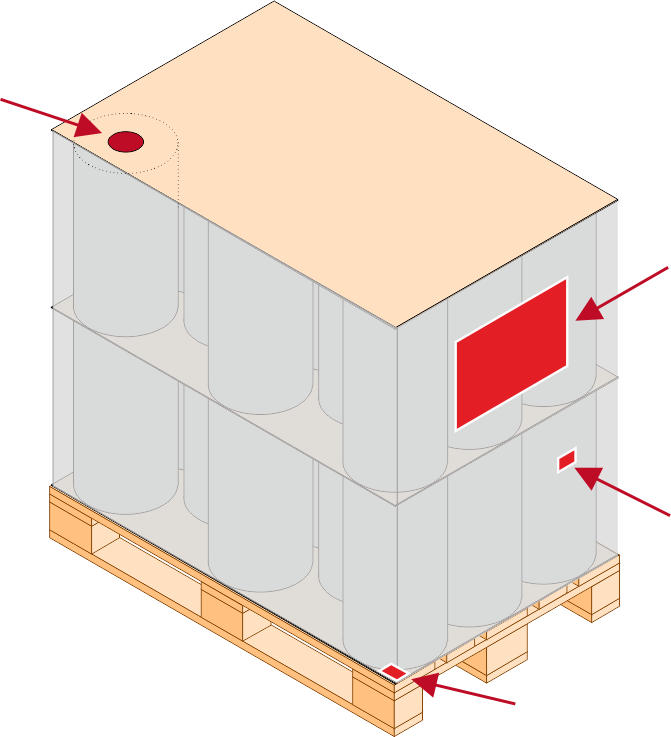

The barcodes on our products provide information about the time of manufacture, the recipe, the raw materials and the control results. Unique barcodes are attached in 4 places. The following pictures describe where the labels are attached.

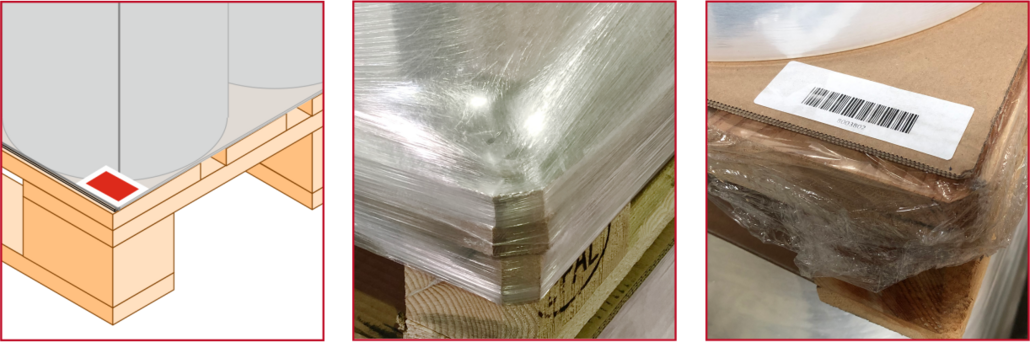

You will find the first production barcode on the front of the pallet (short side).

If you have removed the packaging (a), you will find another production barcode on the underside of the pallet (on the box).

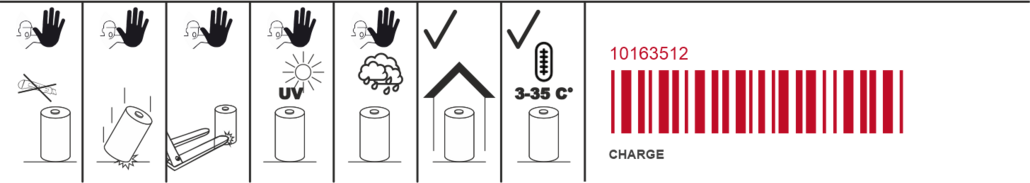

In third place you will find our sales label (exception: it has been replaced by your own label at your request). Here you will find a sales barcode (marked in red)

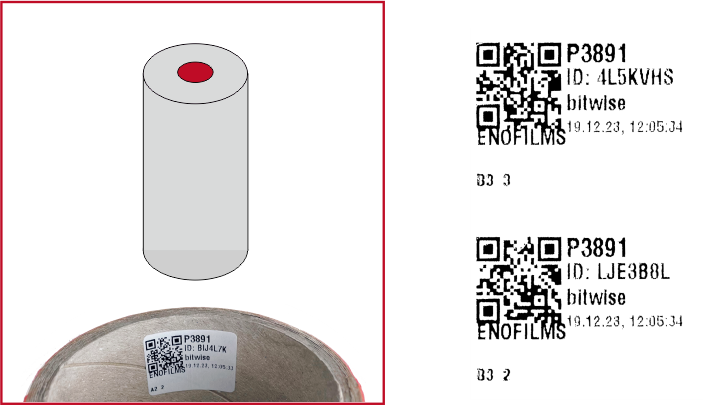

The fourth barcode (QR code) is located on the paper core of each roll of our premium products. This allows us to track the individual rolls.

The traceability of our products (in accordance with Regulation EC No. 1935/2004) is guaranteed by a unique batch number on each pallet (pallet = smallest packaging unit).