ENO®NOcore

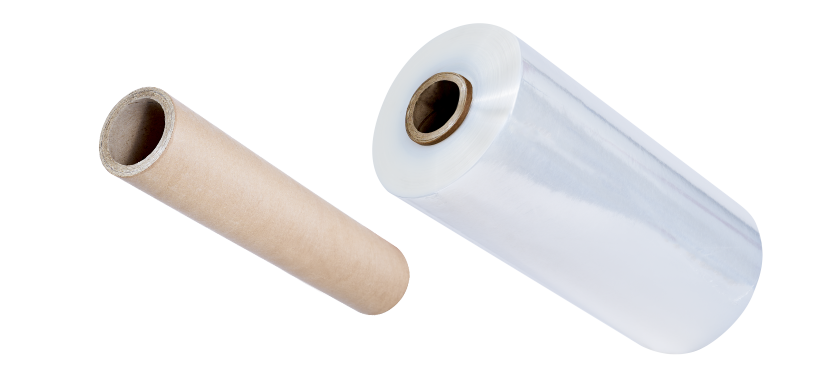

ENO®NOCORE the next REVOLUTION on the stretch film market. After the world’s first stretch film with 67 layers and the lightest core in the world at just 667 g, we are now presenting the coreless version ‘NOcore’.

ENO®NOCORE the next REVOLUTION on the stretch film market. After the world’s first stretch film with 67 layers and the lightest core in the world at just 667 g, we are now presenting the coreless version ‘NOcore’.

ENO®667 is the lightest core in the world at just 667 g.

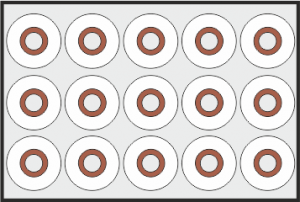

Packing scheme / values per pallet

NOcore | 28 Rollen und 62.700 lfm pro Palette

17μm film with 2240 running metres per roll 0 kg cores | core content 0 % 17.5 kg roll

17μm film with 2240 running metres per roll 0 kg cores | core content 0 % 17.5 kg roll

667g core | 28 rolls and 67,900 linear meters per pallet

17μm film with 2425 running metres per roll 18.7 kg cores | core content 3.4 % 19.6 kg roll

17μm film with 2425 running metres per roll 18.7 kg cores | core content 3.4 % 19.6 kg roll

900g core | 28 rolls and 67,060 linear meters per pallet

17μm film with 2395 running metres per roll 25.2 kg cores 19.6 kg roll

17μm film with 2395 running metres per roll 25.2 kg cores 19.6 kg roll

1200g core | 30 rolls and 62,550 linear meters per pallet

17μm film with 2085 running metres per roll 36 kg cores 17.5 kg roll

17μm film with 2085 running metres per roll 36 kg cores 17.5 kg roll

1600g core | 30 rolls and 55,350 linear meters per pallet

17μm film with 1845 running metres per roll 48 kg cores 16 kg roll

17μm film with 1845 running metres per roll 48 kg cores 16 kg roll